Blog

Water Treatment Technologies to Reduce Chemical Use

Water Treatment Technologies to Reduce Chemical Use [lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

Weighing the Advantages of Different Biological Wastewater Treatment Technologies

Weighing the Advantages of Different Biological Wastewater Treatment Technologies [lwp_divi_breadcrumbs _builder_version="4.21.0"...

Fossil Fuel Transition Means Retirement for Many Coal-Fired Power Plants

Fossil Fuel Transition Means Retirement for Many Coal-Fired Power Plants[lwp_divi_breadcrumbs _builder_version="4.21.0"...

Chip Fab Wastewater Management: Recycling and reuse trends in the semiconductor industry

Chip Fab Wastewater Management: Recycling and reuse trends in the semiconductor industry [lwp_divi_breadcrumbs...

Energy Storage Systems: Impacts & Outlook

Energy Storage Systems: Impacts & Outlook[lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

Electrolysis and Green Hydrogen: Impacts and Outlook

Electrolysis and Green Hydrogen: Impacts and Outlook [lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

Common EPC Project Challenges and How to Prevent Them

Common EPC project challenges and how to prevent them [lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

How Does An EPC Project Work?: Understanding turnkey construction contracts

How does an EPC project work?: Understanding turnkey construction contracts [lwp_divi_breadcrumbs _builder_version="4.21.0"...

Water Recycling and Reuse Systems: Strategies for a smaller carbon footprint

Water recycling and reuse systems: Strategies for a smaller carbon footprint[lwp_divi_breadcrumbs _builder_version="4.21.0"...

Ultrafiltration: Common industrial applications and uses

Ultrafiltration: common industrial applications and uses[lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

What is Ultrafiltration and How Does It Work?

How to Perform an Effective Wastewater Treatability Study [lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

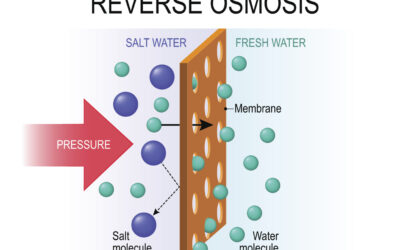

What is Reverse Osmosis and How Is It Used For Industrial Applications?

What is Reverse Osmosis and How Is It Used For Industrial Applications?[lwp_divi_breadcrumbs _builder_version="4.21.0"...

Power Generation and How Water Systems Make or Break It

Power Generation and How Water Systems Make or Break It[lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

What Are the Best Water Treatment Companies for EPC Projects?

What Are the Best Water Treatment Companies for EPC Projects?[lwp_divi_breadcrumbs _builder_version="4.21.0" _module_preset="default"...

Industry Focus: Electronics Industry Trends and What They Mean For Your Water Management Strategy

Industry Focus: Electronics Industry Trends and What They Mean For Your Water Management Strategy [lwp_divi_breadcrumbs...

Industry Focus: Petrochemical and Chemical Industry Trends and What They Mean For Your Wastewater Management Strategy

Industry Focus: Petrochemical and Chemical Industry Trends and What They Mean For Your Wastewater Management...

Working with EPC Contractors: A Q&A with Industry Insiders

Working with EPC Contractors: A Q&A with Industry Insiders [lwp_divi_breadcrumbs _builder_version="4.21.0"...

Industry Focus: How the Power Industry is Evolving and What it Means for Your Wastewater Management Strategy

Industry Focus: How the Power Industry is Evolving and What it Means for Your Wastewater Management Strategy [lwp_divi_breadcrumbs...