Do You Need a Microfiltration or Ultrafiltration Membrane System for Your Plant?

Determining whether or not an industrial plant needs a microfiltration (MF) and/or ultrafiltration (UF) membrane system isn’t always as straightforward as it seems. While these systems are not essential for every industrial process, when thoughtfully implemented within an intake, process, or waste stream, they can go a long way in improving a facility’s efficiency and/or cutting operational costs. Once installed, MF/UF systems are generally inexpensive to run, demanding minimal energy, with maintenance needs mostly confined to the cleaning and/or replacement of filtration system membranes.

It other words, MF/UF can be an extremely cost-effective separation strategy, depending on the needs of your facility.

So “how can you tell if an industrial facility needs an MF/UF membrane system?” This article summarizes the key factors that can help you determine whether or not this type of treatment is necessary for your plant:

Your facility is experiencing downstream fouling

If your plant’s process involves reverse osmosis (RO), nanofiltration (NF), or requires ultrapure process water, then MF/UF may help you cut costs. MF and UF consume less energy and have lower operational costs than other pretreatment technologies, making them a good choice if you’re looking to recover and conserve process water, or replace separation processes with higher operational costs, such as clarification or sand filtration systems. When added to an existing pretreatment strategy, MF/UF can prevent excess wear on downstream equipment by removing contaminant particles, large molecules, and bacteria. Common applications include:

- Pretreatment for RO and NF: MF/UF are used extensively at desalination plants to prevent premature membrane fouling by removing larger contaminant particles prior to passage through RO or NF process trains.

- Protecting downstream equipment: MF/UF efficiently removes contaminant particles from process streams, helping to protect specialized equipment from damage and excess maintenance demands, such as chromatography columns in the biopharmaceutical industry.

You use harsh chemicals or heat for sterilization and potable water generation

If your facility uses chemical disinfectants to generate potable water, then MF/UF might be a cost-saving alternative. Because MF/UF uses filtration membranes to physically capture contaminants from liquid streams, they can reduce your plant’s use of heat and/or chemical disinfectants, such as chlorine or sodium hypochlorite. MF/UF filtration membranes are available with pore sizes ranging all the way down to 0.001 μm, allowing them to safely remove dangerous bacteria, viruses, and pathogenic protozoa without harsh sterilization processes. Using MF/UF for disinfection can help to protect equipment from premature wear, protect the quality of edible products, reduce the complexity of waste treatment processes, and avoid contributing to the growing problem of chemical resistance in infectious agents. Common applications include:

- Sterilization: MF/UF serves as an alternative to heat sterilization for food, beverage, and pharmaceutical industries, removing infectious contaminants while allowing products to retain taste, flavor, and potency.

- Clarification: UF is frequently used to remove insoluble solids from fruit juice and other beverages, and to remove bacteria from meat brine for safe reuse.

Your facility needs to remove suspended solids for discharge

If your industrial facility is concerned with the meeting effluent regulations and reducing disposal costs, MF/UF may help. As a relatively simple separation process, MF/UF and other types of membrane filtration essentially split a liquid stream into two parts—a retentate dense with any particles captured by the filter unit, and a liquid filtrate consisting of any substances small enough to pass through the membrane. This means that MF/UF can be an efficient strategy not only for improving water recovery and recycling capabilities, but also for concentrating spent materials to reduce recycling or disposal costs, and to facilitate recovery of valuable materials. A common application might include the recycling of process materials, such as the use of MF/UF to recover catalysts, dyes, inks, paints, and surfactants from wash water and other process solutions for reuse and recycling.

Industry-specific separation needs

Because of the flexibility afforded by filter unit design and membrane pore size, MF/UF systems can be adapted to fit a variety of other industrial applications, while delivering low operational costs. Some examples of MF/UF industrial applications include:

Power

In the power industry, high purity water is often needed for key processes such as steam generation. Increasingly, MF/UF membranes are being used for suspended solids removal, replacing less efficient multi-step pretreatment processes, such as clarification followed by media filtration.

Refinery

New drilling technologies in the refinery industry, such as bituminous sand and hydraulic fracturing, produce large amounts of waste water. MF/UF are used to efficiently separate oil and other contaminants from process water, helping to cut costs by promoting reuse of process water and minimizing discharge streams.

Petrochemical and chemical

In the petrochemical and chemical industries, MF/UF are used for a wide variety of applications, including pretreatment for RO, purification of dyes, pigments and optical brighteners, treatment of wastewater and process water, as well as removal and concentration of materials such as minerals, metals, titanium dioxide, and calcium carbonate.

Oil and gas

MF/UF membranes are used to support water reuse in areas where source water is scarce or expensive. Recent advancements in filtration membrane technology have also made continuous fermentation a viable alternative to the traditional batched process, further improving efficiency, especially in the production of ethanol.

Mining and metals

In the mining industry, MF/UF is used to recover of metals from process streams, to pretreat seawater prior to RO, and to treat mining waste water, including acid mine drainage and tailings.

Food and beverage

MF/UF is commonly used in the food industry to concentrate and/or remove specific protein molecules from liquid streams. This can include concentration of proteins in egg whites, separation of whey protein, and concentration of vegetable and plant proteins. In the beverage industry, MF/UF are increasingly used for removal of microbial particles and proteins after fermentation, and improved product recovery. In some cases, MF/UF is also used to remove alcohol content from wine and beer.

Municipal

The municipal water industry depends on MF/UF for efficient removal of contaminants such as bacteria and viruses from drinking water, as well as pretreatment to protect RO equipment from damaging solids present in source water.

How SAMCO can help?

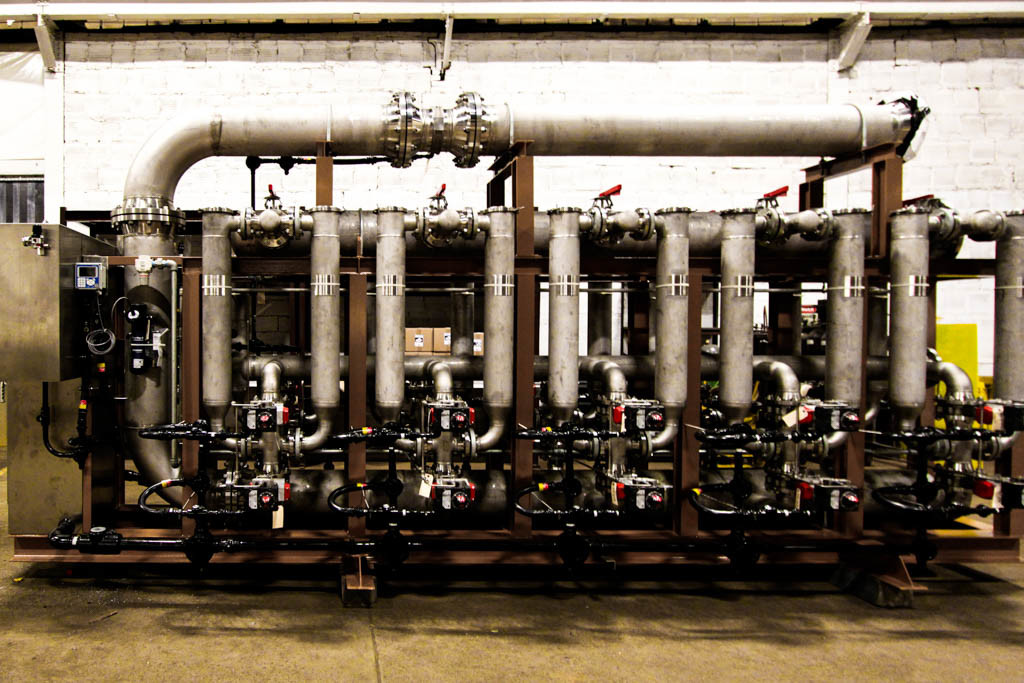

SAMCO has over 40 years’ experience custom-designing and manufacturing MF/UF systems for a range of industries and solutions, so please feel free to reach out to us with your questions. For more information or to get in touch, contact us here to set up a consultation with an engineer or request a quote. We can walk you through the steps for developing the proper solution and realistic cost for your MF/UF treatment system needs.

To learn more about SAMCO’s MF/UF technologies and services, visit our microfiltration / ultrafiltration page here.

Some other articles about microfiltration and ultrafiltration membrane systems you might be interested in include:

- How to Choose the Best Microfiltration and Ultrafiltration Systems for Your Facility

- How Much Do Microfiltration and Ultrafiltration Membrane Systems Cost?

- What are Microfiltration and Ultrafiltration and How Do They Work?

- Microfiltration and Ultrafiltration Membrane Systems: Common Problems and How to Fix Them

- Microfiltration vs Ultrafiltration Processes: What is the Difference?

- What Are the Best Companies for Microfiltration and Ultrafiltration Membrane Systems?