Zero Liquid Discharge

Do you need to decrease your facility’s water footprint?

With tightening regulations on using water and discharging liquid waste, zero liquid discharge (ZLD) could be the answer.

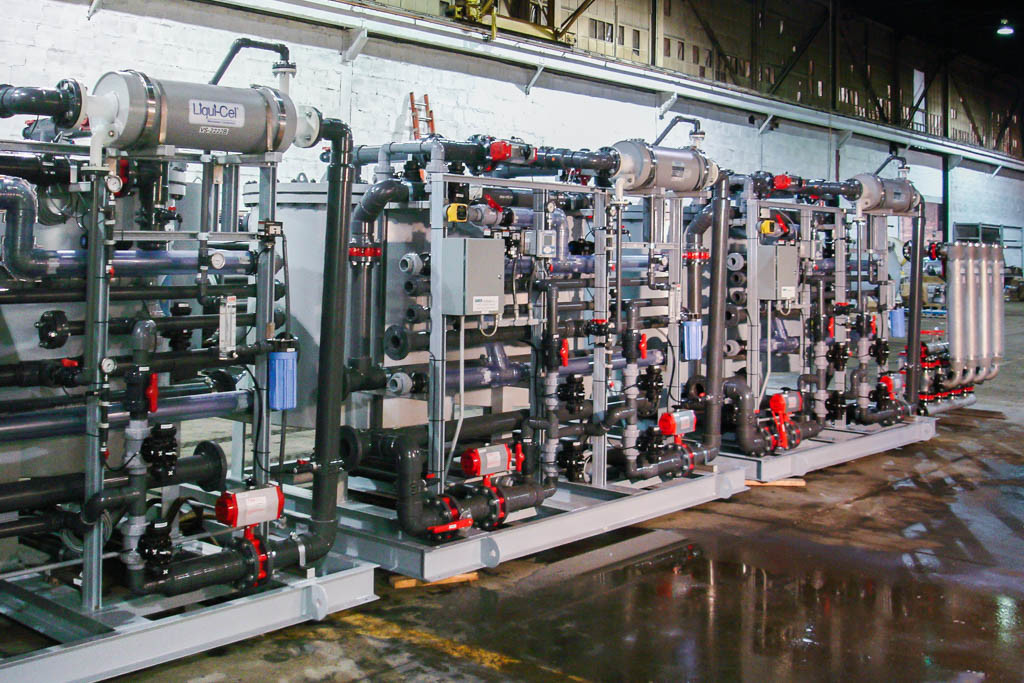

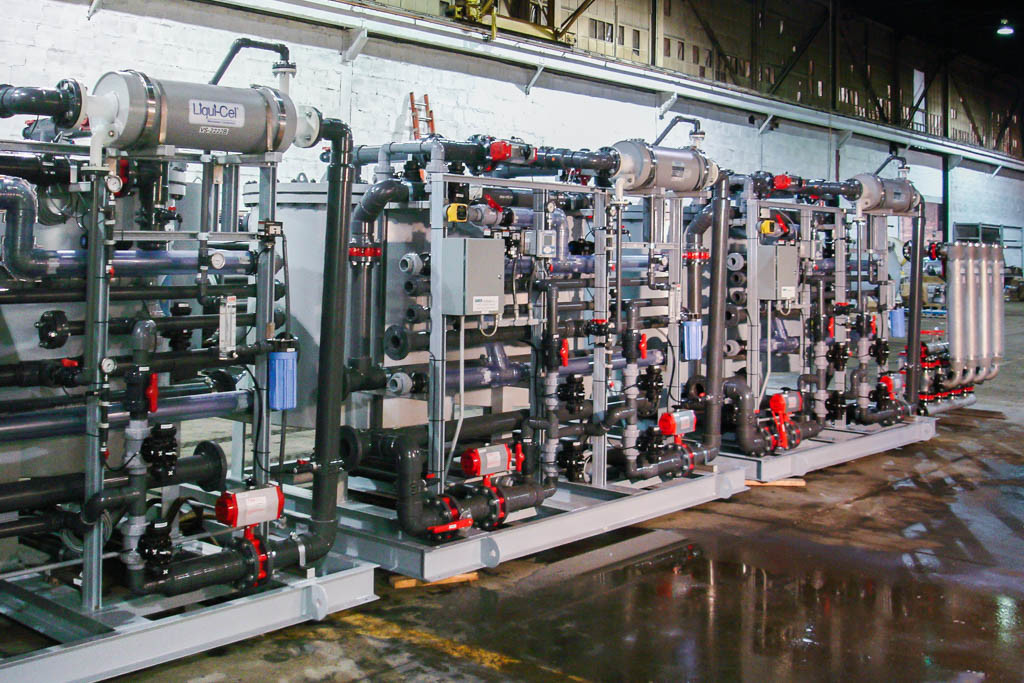

Wastewater can often be difficult to manage, especially when local regulations prohibit discharge or enforce stringent effluent quality requirements. SAMCO offers a range of technologies that can help you treat and recycle discharge waters back into your process for reuse, a technique that recovers all fluid waste by utilizing our state-of-the-art filtration and thermal technologies.

The specific technologies that will make up a facility’s ZLD treatment system will vary depending on the volume of dissolved material present in the waste, the system’s required flow rate, and what specific contaminants are present, but will generally consist of a three-step process with the following “blocks” of treatment:

-

- Pretreatment and conditioning: removes simple things from the wastewater stream that can be filtered or precipitated out, conditioning the water and reducing the suspended solids and materials that would otherwise scale and/or foul following treatment steps.

- Phase-one concentration: typically done with membranes like reverse osmosis (RO), brine concentrators, or electrodialysis. These technologies take this stream and concentrate it down to a high salinity and pull out up to 60–80% of the water.

- Evaporation/crystallization: after the concentration step is complete, the next step is generating a solidthrough thermal processes or evaporation. It is collected and reused. The leftover waste then goes from an evaporator to a crystallizer, which continues to boil off all the water until all the impurities in the water crystallize and are filtered out as a solid.

The specific technologies that will make up a facility’s ZLD treatment system will vary depending on the volume of dissolved material present in the waste, the system’s required flow rate, and what specific contaminants are present, but will generally consist of a three-step process with the following “blocks” of treatment:

-

- Pretreatment and conditioning: removes simple things from the wastewater stream that can be filtered or precipitated out, conditioning the water and reducing the suspended solids and materials that would otherwise scale and/or foul following treatment steps.

- Phase-one concentration: typically done with membranes like reverse osmosis (RO), brine concentrators, or electrodialysis. These technologies take this stream and concentrate it down to a high salinity and pull out up to 60–80% of the water.

- Evaporation/crystallization: after the concentration step is complete, the next step is generating a solidthrough thermal processes or evaporation. It is collected and reused. The leftover waste then goes from an evaporator to a crystallizer, which continues to boil off all the water until all the impurities in the water crystallize and are filtered out as a solid.